A Chemistry Set for Experts

Dirk Steinhilber has developed a method of producing highly tolerable nanogels and microgels. Researchers hope they will help to revolutionize treatment of serious diseases.

May 18, 2016

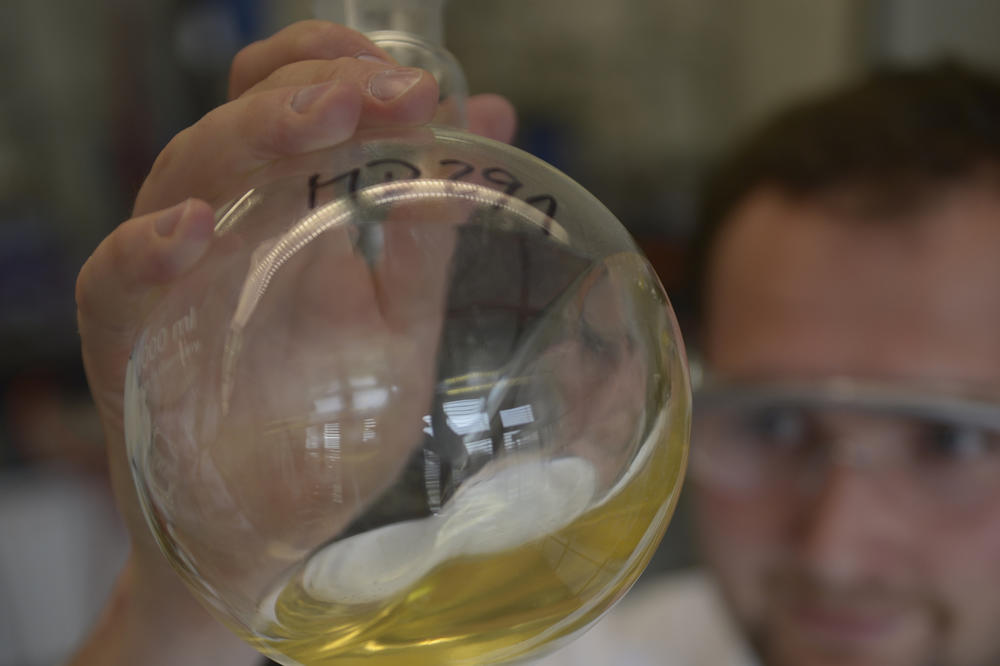

Hope is golden colored and slippery. It is kept in flasks in the refrigerators at the Institute of Chemistry and Biochemistry at Freie Universität in Dahlem, where it is now produced by the kilogram. Polyglycerol is its name, and it is a highly promising base material for hydrogel particles.

Hope in golden yellow: Mathias Dimde, a research associate on the team headed by Dirk Steinhilber and Professor Rainer Haag, turns a flask containing dendritic polyglycerol.

Image Credit: Bernd Wannenmacher

For about 15 years now, researchers all over the world have been hoping that these kinds of gels can be used someday to cure cancer, diabetes, Alzheimer’s disease, Ebola – and perhaps even AIDS.

There is a long way to go. Still, one graduate of Freie Universität has given medical and pharmaceutical researchers a way to speed up the process. Dirk Steinhilber has developed a modular system that can be used to easily produce microgels for a wide range of applications. “Developing this method was a lot of work,” says Steinhilber, 32. “But the only thing left to do at this point is to put the two things together,” he continues. In the future, he says, it would be conceivable for companies to buy the basic substances and mix them according to a formula.

To understand why researchers are focusing so much on hydrogels, a closer look at these substances is needed. In consistency and color, the gel is much like a melted gummy bear. And in fact, there are great similarities. Both are made from soft matter, from a substance that is neither solid nor liquid, so it has special properties – including being able to absorb water like a sponge.

At the microscopic level, the artificial gel consists of a network of very large molecules with three-dimensional bonds. These are known as polymers. Chemists can attach and insert other molecules at the ends of the polymers and in the “niches” in between. These include active medical ingredients, for example, or therapeutic proteins, which can then be transported to certain places in the body. The microgels can also be designed to lock viruses away, or to surround living cells. If a treatment requires very small units, they can be shrunk down into nanogels.

Because the gels absorb a great deal of water, the human immune system does not perceive them as foreign bodies. With this kind of water encapsulation, insulin-producing islet cells could be channeled into the body of a patient with diabetes, for example. The body’s natural defensive reflex in response to the gelled-in cells would be minor, and it would taper off completely after about two weeks.

Chemists can insert substances into the gel that ensure that the gel envelope dissolves after exactly this span of time – like a predetermined breaking point on a timer. Freed of its encapsulation, the new islet cell could then produce insulin on a long-term basis. Cancer patients, in turn, could receive injections of active ingredients that destroy tumors in gel capsules. The microgel would be designed in such a way that the capsule would dissolve as soon as it reached the acidic pH value of diseased tissue – delivering the chemotherapy right there, not throughout the entire body.

The polymers themselves have no known adverse health effects. The challenge is how to put them together. In the lab, chemists could theoretically bring out the “big guns” to create the bonds between the polymer and other substances. But if the microgel takes effect inside the body, it dissolves these bonds again once it is there. This means that the researchers have to consider early on during the assembly process whether the byproducts of the later breakdown process could possibly harm the organism.

With this in mind, Steinhilber is looking for a method in which the reaction causes as little strain in the body as possible. “I’ve spent a long time making sure the process proceeds at room temperature, quickly, without catalysts and without byproducts,” he says. He has developed various methods of building microgels and nanogels. “Implementation is very simple, and you can give the polymers all of the possible functions anyway.” Steinhilber’s method can even be used to control when the microgels dissolve later on.

At the end of Steinhilber’s research came a dissertation, for which he was recently awarded the Bruno Heck Science Prize. The judges had special praise for the focus on application that was present in his research. That is something that has always been important to Steinhilber. It was why he initially started his studies at a university of applied sciences before moving to Freie Universität to take up a position in the working group headed by chemistry professor Rainer Haag. “In our group, it’s a given that right from the start, you need to include the idea of something useful being produced as part of your considerations,” Steinhilber says.

His idea will be spared the fate of many developments – namely, ending up collecting dust on a shelf somewhere. For example, the basic substance, polyglycerol, is now being produced in a wide range of versions on a tailored basis in Dahlem.

In another application, researchers at the interdisciplinary Nanoscale focus area, which deals with functional materials at the nanoscale, are using Steinhilber’s modular components to reduce the side effects of medications designed to treat inflammatory skin diseases. And Dendropharm GmbH, a spinoff of Freie Universität, is planning to use Steinhilber’s method to develop nanogels that can be tested in veterinary medicine.

At this point, it has been a long time since the refrigerators in Dahlem held just one hope – they now hold many.

Further Information

Dirk Steinhilber, Bruno Heck Science Prize Winner, Email: steinhilberdirk@gmail.com